I have previously recommended on here, to use Loctite 638, to 'glue' the sprocket on.

This is the acknowledged fixed on the DRZ400 which suffers from the same problem (I know its happened to me, and I also done the fix which has also worked and stopped it coming loose)- namely the Gearbox sprocket nut becoming loose (usually followed by the Oil seal failing, and after a few repeated loosenings, the transmission locking up)

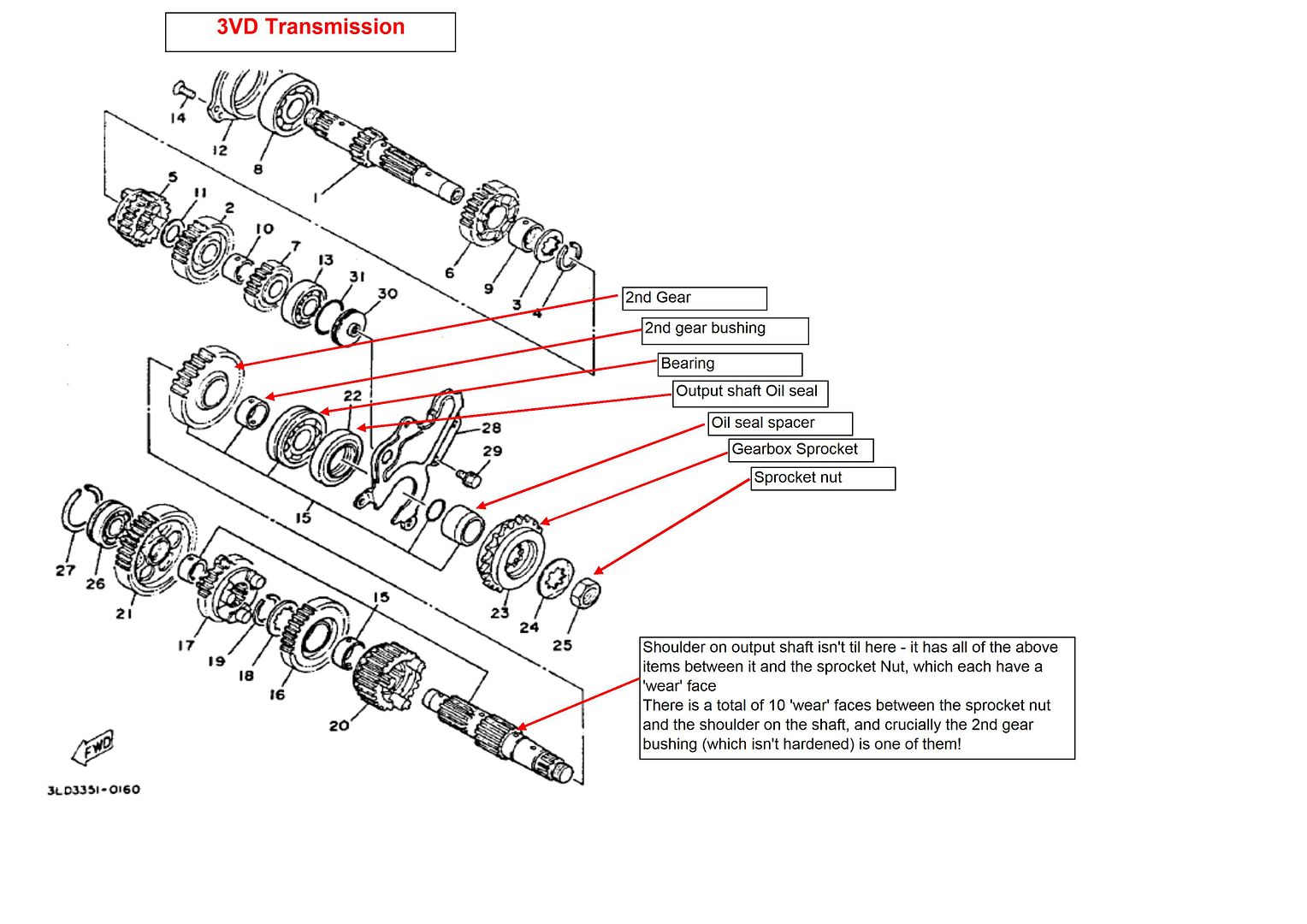

The problem with the DRZ400 is that the clamping pressure from the gearbox sprocket nut has to go through the sprocket, then the oil seal spacer, then the bearing then the 2nd gear bushing before it clamps against the shoulder on the output shaft

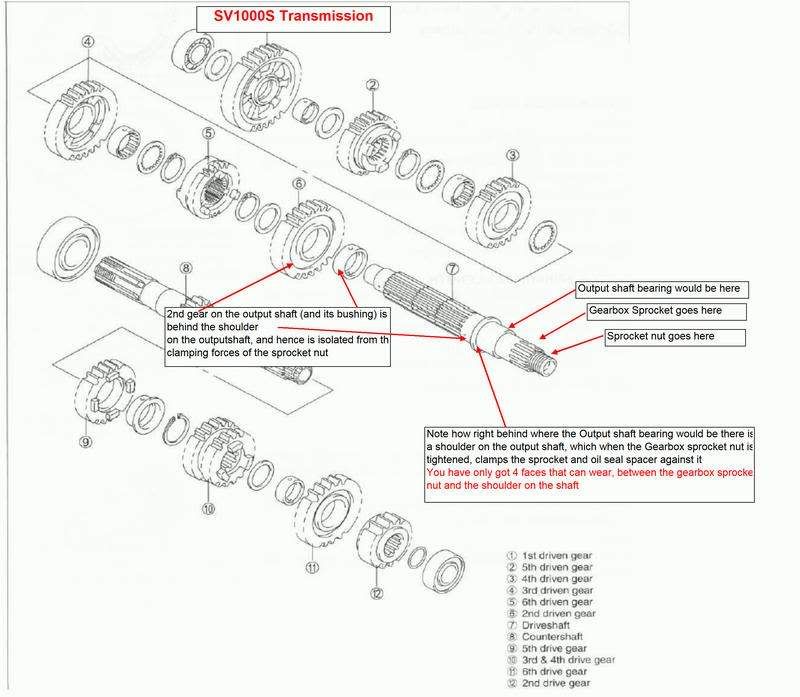

On 99% of bikes, this shoulder on the output shaft is right behind the bearing, and the 2nd gear bushing is the other side, isolated from the clamping pressure of the nut, and the slight rocking motion of the sprocket on the splines.

It is the slight rocking motion of the sprocket which causes the 2nd gear bushing to wear, and hence the nut to appear loose (the nut doesn't come loose, its the wear of the 2nd gear bushing allowing the clamping pressure to slacken off - the nut can't come loose as its held in place by the bent over tab washer behind the sprocket nut)

Looking at the 3VD microfiche of the transmission, it has EXACTLY the same set up as the DRZ400

On most bikes the set up is like this (this is from a Suzuki SV1000)

You can see that the shoulder on the output shaft is right behind where the bearing would be, and the 2nd gear bushing is on the other side

So, its clear to me, if you don't want your front sprocket nut to come loose and trash your output shaft then use Loctite 638 to glue it in place

The normal loctitie from halfords etc ain't no good -its got to be 638 available from industrial stockists etc

You'll need a 3 legged puller to get the sprocket off when its time to change it, but I can guarantee it won't come loose

Edited by GuyGraham, 20 November 2007 - 07:59 pm.